From insight to implementation, I bridge creative problem-solving with technical execution.

I approach design holistically — defining user and business needs, iterating through prototype-driven development, and refining production engineering. Each project blends design intent with DFM realities, ensuring ideas scale seamlessly from prototype to manufacture.

I take end-to-end ownership of hardware: enclosure architecture, mechanism design, prototyping, and tolerance-driven detailing through to production hand-off. I collaborate closely with electronics and software teams, but my focus is on every physical element — usability, assembly fit, reliability, and serviceability — so each product is both elegant and buildable.

These are my tools.

Case Studies

Click to view project breakdown

Biomedical Projects

Click to view project breakdown

Experience

Industrial Designer - BSD Robotics (2021-2025) laboratory instrument design and manufacturer

Previous Duties

Build a design record system for maintenance / service manual.

Develop and progress new instrument design projects that involve materials handling and sample preparation steps with user experience as a key consideration.

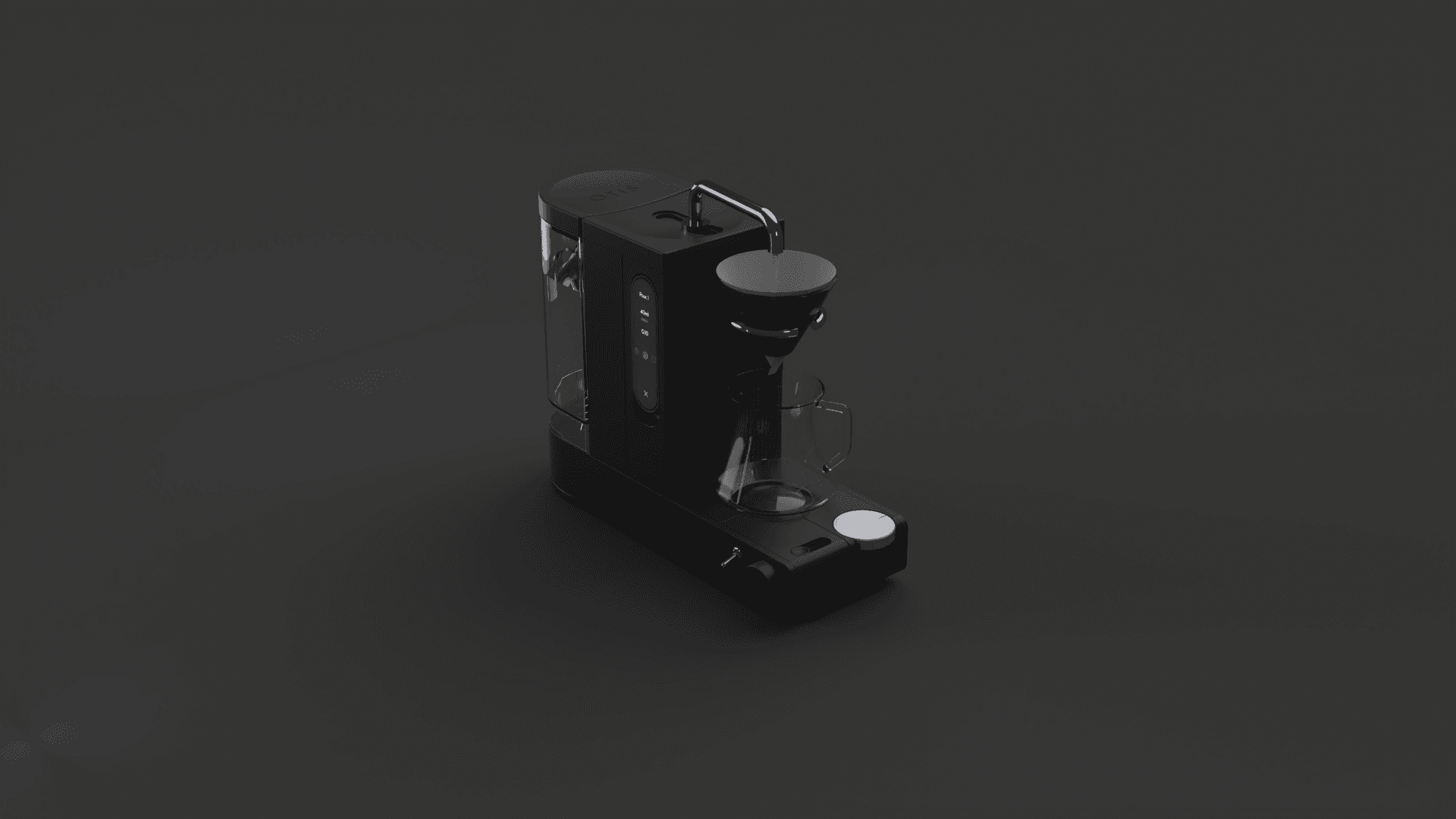

Create and develop designs from specifications, from concept, to production ready design. Perform image renders and animations for concept review and liaison with sales and marketing for product promotions and technical documentation.

Develop and maintain knowledge of relevant laboratory application areas and understand key criteria for successful product implementation and features.

Skills

Solidworks for 3D model and 2D engineering drawings (GD&T)

Prototype design and asssembly

Keyshot Rendering for marketing visual asset and animation

Qualification

Bachelor of Industrial design (2013-2017)

Queensland University of Technology (QUT)